The custom printing industry is evolving rapidly. Apparel brands, local boutiques, and promotional product companies are demanding faster turnaround times, lower minimums, and greater design flexibility. For print shop owners, meeting these expectations requires technology that balances efficiency, quality, and profitability. This is where DTF Transfers including UV DTF solutions present a compelling business opportunity.

Adding UV DTF capabilities alongside traditional apparel DTF printing allows print shops to expand into new markets, increase margins, and better serve seasonal collections without increasing operational risk.

Expanding Revenue Beyond Apparel

Traditional DTF Transfers have already transformed garment decoration. Print shops can produce full-color, high-detail transfers and heat-press them onto cotton, polyester, blends, and performance fabrics with minimal setup.

However, UV DTF extends this capability beyond fabric. With UV DTF technology, print shops can apply durable, high-resolution graphics to hard surfaces such as:

- Tumblers and drinkware

- Phone cases

- Packaging boxes

- Promotional merchandise

- Store signage

For apparel brands and boutiques, this creates bundled opportunities. A New Year clothing collection, for example, can now include matching branded accessories, stickers, or packaging elements all produced in-house by the same print partner.

By offering both garment-focused DTF Transfers and UV surface applications, print shops position themselves as full-service production partners rather than single-service vendors.

See also: The Role of Technology in Customer Relationship Management

Supporting Seasonal Apparel Collections

Seasonal collections are a major revenue driver for apparel companies and local boutiques. Holidays, local events, and limited-edition drops generate strong short-term demand—but they also come with inventory risks.

DTF Transfers reduce that risk dramatically.

Instead of screen printing hundreds of garments in advance, brands can:

- Order transfers in bulk

- Store them flat without taking up significant space

- Apply designs only when garments are sold

This on-demand approach allows boutiques to test multiple seasonal graphics without committing to large pre-printed runs. When a design sells out, it can be restocked quickly. When demand slows, production stops immediately—no excess printed inventory.

UV DTF further enhances seasonal campaigns by enabling coordinated hard goods such as branded gift packaging or promotional decals to match apparel themes.

Lower Setup Costs, Higher Margins

From a financial standpoint, DTF Transfers offer strong unit economics.

Compared to screen printing, DTF eliminates:

- Screen setup fees

- Color separation limitations

- Large minimum order requirements

This makes short runs and complex full-color designs economically viable. For print shops, that translates into higher-margin small-batch orders that would not be profitable using traditional methods.

UV DTF operates similarly. There is minimal setup time between jobs, and intricate multicolor artwork does not significantly increase production cost. As a result, print shops can confidently accept:

- Limited boutique runs

- Personalized orders

- Event-based merchandise

- Influencer or micro-brand drops

The flexibility increases customer retention while protecting profitability.

Faster Turnaround During Peak Demand

Seasonal spikes—such as holidays or local festivals—often strain print shop capacity. Traditional production methods can slow down during high-volume periods due to setup requirements and curing times.

With DTF Transfers, production can be streamlined:

- Print transfers in advance using gang sheets.

- Store them until orders arrive.

- Heat press designs in minutes.

This modular workflow separates printing from garment application, allowing shops to manage labor more efficiently.

UV DTF adds another layer of speed. Hard goods decoration becomes a peel-and-apply process rather than a complex multi-step print setup. For boutiques needing last-minute inventory restocks, this speed is a competitive advantage.

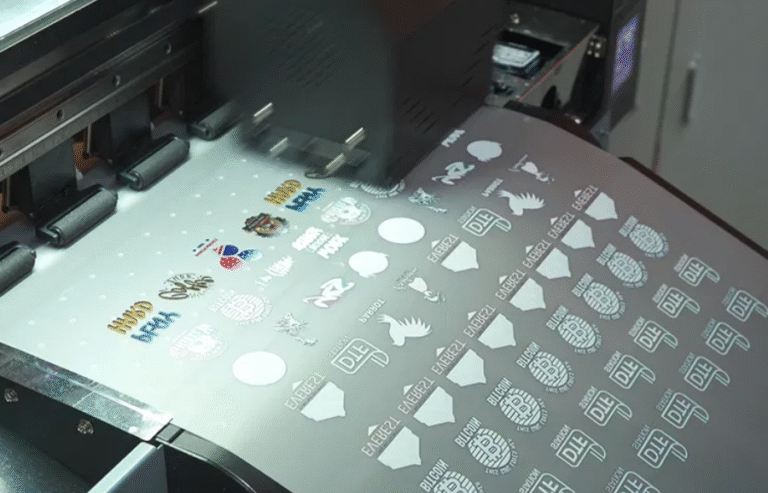

Improved Workflow Efficiency with Gang Sheets

Modern print shops maximize efficiency using gang sheet layouts. By organizing multiple designs onto a single sheet, businesses reduce film waste and improve print throughput.

When offering DTF Transfers, gang sheet strategies allow shops to:

- Combine multiple client designs into one production run

- Reduce per-unit costs

- Optimize printer usage

The same principle applies to UV DTF production. Efficient layout planning ensures that both apparel transfers and hard-surface graphics are produced with minimal material waste.

For B2B clients, this efficiency translates into better pricing and faster delivery—two factors that strongly influence repeat business.

Meeting Boutique Expectations for Quality

Local boutiques prioritize premium aesthetics. Colors must be vibrant, edges clean, and prints durable. Poor-quality decoration reflects directly on the boutique’s brand.

Modern DTF Transfers produce:

- High-resolution detail

- Strong wash durability

- Consistent color output

UV DTF applications offer scratch-resistant and fade-resistant results on hard goods, further elevating perceived product value.

By delivering reliable quality across apparel and accessories, print shops strengthen long-term partnerships with retailers.

A Strategic Growth Move for Print Shops

Offering UV capabilities alongside garment-focused DTF Transfers is not simply a technology upgrade it is a strategic business expansion.

Print shops gain:

- Access to new product categories

- Increased average order value

- Stronger appeal to seasonal apparel brands

- Reduced production risk compared to traditional methods

As apparel companies and local boutiques continue shifting toward smaller, more frequent seasonal drops, demand for flexible printing solutions will only increase.

Conclusion

The business case for offering UV and garment-based DTF Transfers is clear. Print shops that invest in this technology can serve apparel brands more effectively, reduce production bottlenecks, and unlock new revenue streams beyond fabric decoration.

In a market defined by speed, customization, and seasonal agility, DTF technology is no longer optional; it is a competitive necessity.